Mechanical seals are increasingly used by engineers and network owners in fibre installation projects across the globe.

Traditional heatshrink methods for cable sealing are time consuming; dependent on the skill of the engineer; and the access required around the port means heatshrink is not conducive to high port densities, particularly applicable in today’s FTTX environment. There are also health and safety concerns relating to gas bottle storage/transportation and confined space use.

HellermannTyton’s patented cablelok mechanical seal enables fast safe cable installation, providing a highly repeatable and consistent seal between the cable and the closure port with excellent non-leak performance. Tested to in excess of 6m head of water, the cablelok does not rely on the skill and experience of the engineer to achieve the required seal, whilst installation times are typically reduced by up to 90%.

View in 3D

You can spin around (swipe or click and hold left hand mouse button), zoom in (pinch fingers or rollerball on your mouse) and open the lid/tray by clicking on the top navigation buttons.

Engineered with both the application, user and network installer in mind, Cablelok offers:

Durability

Versatility

Ease of use

Flexibility

Each port size on a HellermannTyton fibre closure has a unique identifier and a dedicated series of Cablelok seals (ie: R, B, S, T, D, LM or L).

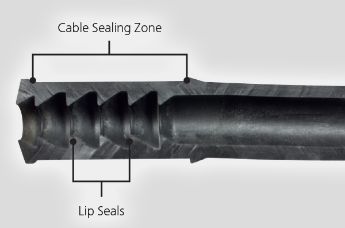

Unlike heatshrink, that requires direct heat, sealing is achieved by multiple internal lip seals which are compressed onto the cable during installation.

This method of sealing eliminates the need for potentially hazardous gas bottle transportation and storage and is ideal for use in hazardous or restricted areas as no heat or gas is required for installation.

Step 1: Choose correct sized Cablelok for your cable and port size.

Step 2: Clean and lubricate the cable and opened port.

Step 3: Insert the cable through the base.

Step 4: Lubricate the Cablelok and thread onto cable.

Step 5: Pull Cablelok through port until seals are seated.